Document created: 21 March 01

Air University

Review, July-August

1982

A Uniform National Air-Cargo System

Do we need

it?

Paul D. Tuck

|

Victory is the beautiful, bright -colored flower. Transport is the stem without which it could never have blossomed. |

|

Winston Churchill The River War, 1899 |

Before the development of the Air Force’s 463L Materials-Handling System, individual pieces of cargo were floor-loaded by hand. However, as aircraft grew in size and productivity, cargo-handling and aircraft-loading efficiency were upgraded. The changes involved areas like the in-plane air-cargo systems, materials-handling equipment (MHE), and containers and pallet/net combinations, known as unit-load devices (ULDs). Military and civil transport aircraft were originally handled in the same way. But significant differences between the two airlift systems have evolved over the years. These differences recently led to the expression by the Department of Defense of a requirement for increased interoperability between military and civil air-cargo systems.1

The reverses that the United States and the free world have suffered in the Middle East, Africa, and Central America during the last decade have served to intensify our nation’s urgent need for availability, on short notice, of a standardized airlift system for rapid deployment of cargo and troops, especially to remote areas.

The current airlift components of our system are the United States Air Force Military Airlift Command (MAC) and the Civil Reserve Air Fleet (CRAF) and their aircraft, ground-support equipment, services, and personnel. During peacetime, the two airlift agencies have differing needs and interests. During conflict, they have the same mission: to move war materials rapidly to the conflict area or areas. The military system relies heavily on the 88" X 108" pallets of the 463L Materials-Handling System. The civil system relies to a greater extent on containers and the 88" or 96" X 125" civil pallets.

There is also a lack of compatibility between military transport aircraft and civil aircraft. The 108" gauge rail systems in military aircraft (designed to handle pallets with a secondary function of airdrop) are not adjustable. On the other hand, the civil rail systems are adjustable, so as to accommodate varying sizes of pallets and other unit-load devices.2

Advances in the development of transport aircraft have historically paced development of complementary ground systems. This portion of the military materials-handling equipment specifically designed for the 463L system will not rise high enough to reach the upper decks of the newer wide-bodied aircraft, and civil cargo loaders generally cannot be lowered to interface with the truck-bed height of military aircraft.3 However, the Air Force is procuring additional commercial equipment to meet wide-body needs.

Although interoperability needs to be improved, a modest level of interoperability does presently exist. Civil cargo-capable aircraft can accept 463L system pallets, but military aircraft cannot accept civil pallets. This level of civil interoperability results from airline responsibility under CRAF contracts; the carrier’s need to interline (i.e., transport ULDs of varying dimensions between different airlines); and the need to transfer ULDs between different types of aircraft within individual airlines.4

If unit-load devices were fully interchangeable between civil and military aircraft, the total number of ULDs required by the two airlift systems could be reduced. At present, MAC provides 463L system pallets for both their military aircraft and civil contract aircraft operating in support of military operations. The pallets and containers owned or leased by the CRAF carriers represent additional resources that are largely disregarded for military airlift, even when civil-contract aircraft are used.

Essentially the same situation prevails with respect to the materials-handling equipment. MAC furnishes the MHE to service its organic military aircraft and has historically furnished the cargo loaders (and loading crews) when civil cargo-capable aircraft operate through military airfields.

If MHE interoperability were to be enhanced, the purchase and maintenance of duplicate sets of civil and military MHE could be avoided, or at least substantially reduced.5 Aircraft productivity is directly influenced by the number and type of ULDs used. For example, the stretched DC-8 can transport eighteen 463L system 88" X 108" pallets, or eighteen 88" X 125" civil pallets. The DC-8 productivity in cargo carried is increased about 11 percent when civil, rather than military, pallets are used.6

Early collaboration between military and civil planners during the design phase could help in exploring the design of interoperability into in-plane air-cargo systems, MHE, and ULDs. For example:

• Future military transports might be designed with slightly higher cargo decks and civil-cargo loaders with a lower profile so the civil loader could service the military aircraft.

• Adjustable-gauge rail systems in military aircraft and the installation of end locks could result in use of civil ULDs and constitute an additional resource that is largely untapped.

• New Air Force cargo loaders might be designed to reach the main decks of wide bodies.

As we rely more on civil carriers during contingency operations, this planning could greatly enhance the overall productivity of joint civil and military systems.

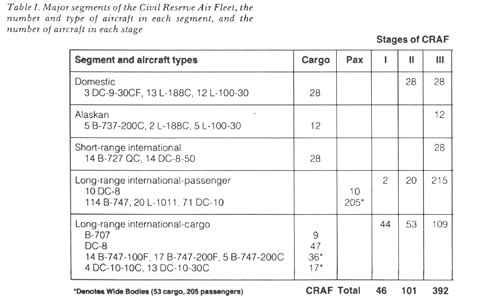

The major segments and aircraft types, whether cargo or passenger (Pax) aircraft, and the number of aircraft in each stage of the Civil Reserve Air Fleet are shown in Table I. The domestic CRAF is based primarily on the need for wartime expansion of the Air Force Logistics Airlift (LOGAIR) and the Navy Quick Transportation (QUICKTRANS) peacetime-cargo airlift.

LOGAIR and QUICKTRANS are airlift systems operated by civil carriers under contract to airlift traffic between major facilities of the services. The Alaskan CRAF was formally established in January 1968 to support unique requirements, such as the distant early warning (DEW) line. The short-range international CRAF provides the airlift for inter-island operations and between the continental United States (CONUS) and such areas as the Caribbean, Greenland, Alaska, and Iceland.

The long-range international CRAF augments the Military Airlift Command. Plans provide for three incremental activation stages based on airlift needs:

Stage I consists of 46 long-range aircraft that can be activated during a surge by the Commander in Chief, Military Airlift Command (CINCMAC).

Stage II consists of 101 aircraft and can be activated during an emergency by the Secretary of Defense.

Stage III contains 392 aircraft (including those in Stages I and II) that can be activated during full mobilization only after a national emergency has been declared by the President or Congress.

The response time for activation of Stages I and II is 24 hours; for Stage III, it is 48 hours.

Of the total CRAF inventory of 392 aircraft, there are 258 wide-bodies (205 passenger; and 53 cargo). The letter "F" means a pure freighter, specifically designed and built to carry freight. "C" stands for convertible, an aircraft that can be configured to carry passengers and/ or cargo. "QC" means quick change (from cargo configuration to passenger or vice versa). The CRAF inventory changes from time to time for such reasons as sale, lease, loss, or receipt of new aircraft.7

During peacetime, the needs and interests of the military and civil airlift systems are different; in wartime, they are almost identical. The military 463L system relies heavily on the 88" X 108" pallet; the civil system relies more on containers and the 88" or 96" X 125" pallets.

Military aircaraft (except the KC-10A) cannot carry civil pallets or standard containers unless the containers are lashed to 463L system pallets; civil aircraft can accommodate military pallets, since their rails can be adjusted to gauges of varying widths.

In civil-airlift operations, pallets and containers are routinely intermixed. The in-plane air-cargo systems as well as the materials-handling equipment, scarcely "know" the difference between pallets and containers. Military 463 L MHE will not reach the upper decks of wide-bodied aircraft and, in general, civil-cargo loaders cannot be lowered to the truckbed height of military aircraft. The C-130/ C-141 /C-5 all engage the notches in the 463L system pallets at the outboard edges by locks in the rail system; civil aircraft normally restrain pallets by guide rails at the outboard edges and by end locks (latches) forward and aft. 8 The 40K-Transporter Loader is the principal military loader used for loading / offloading military aircraft. Characteristics of the 40K-Transporter Loader are as follows:

| Characteristics | feet | inches | ||

| lifting capability -- 40,000 pounds |

elevating height |

[max [min |

13 3 |

0 4 |

| lifting/lowering speed--feet per minute (FPM)--10 |

platform length |

41 | 5 | |

| number of 463L system pallets accommodate--5 |

platform width | 10 | 0 |

The family of 25, 40 and 55K-loaders is not usable for wide-bodied aircraft because of insufficient lifting height. The K-loaders are normally used in conjunction with loaded 463L system military pallets and aircraft rail systems. The 40K had roller conveyers on the deck. However, the floor is not powered: pallets or other cargo must be pushed or winched between the loader and aircraft decks. The 40K does not have side-transfer capability.

A one-man cab is located at the left front corner of the deck of the 40K-Transporter Loader. Two hydraulically operating folding links raise and lower the deck and provide fore-and-aft tilt. Four small hydraulic cylinders roll the deck from side-to-side. The 40K loader has been in use about 17 years.

The 463L system pallet’s outer dimensions measure 108" wide, 88" long, and 2 1/4" thick. It has a nominal weight of 290 pounds. The 463L system pallet is used in conjunction with three webbed restraint nets (two side and one top) that weigh an additional 65 pounds, for a total of 355 pounds for the pallet/nets combination.

The top and bottom pallet surfaces are both flat and smooth. The pallet edges are equipped with rails that are indented every ten inches on center, thereby permitting an interface with the locks in the aircraft-restraint rails. Pallet restraint within the aircraft is normally accomplished only along the 88-inch dimension, since it is oriented laterally in the 108-inch dimension. Vertical restraint is provided by the aircraft restraint rails and a floor-mounted roller-conveyer system, while fore and aft restraint is provided by the aircraft-restraint rail locks inserted into the pallet-rail indentations.

Cargo-restraint devices may be attached to the twenty-two 7500-pound tie-down rings located symmetrically around the pallet perimeter (6 along each 108" side and 5 along each 88" side). The rigid structural design consists of a balsa-wood core and aluminum-alloy skin. The principal unitization device for military-aircraft operations has a theoretical loading volume of 528 cubic feet and can carry a maximum weight of 10,000 pounds.

Prior to the 463L system pallet, individual pieces of cargo were handled manually when aircraft were bulk loaded. Of particular importance is the fact that 463L system pallets can be built up during lulls in the cargo-terminal workload. They can then be quickly placed aboard departing aircraft at any time. In one sense, when building up pallets, one is actually loading the aircraft.9

The C-141 was the first military transport to have the military aircraft rail-and-roller conveyer system built in as an integral part of the new aircraft. The C-130 aircraft was retrofitted. The C-5 and other cargo-capable, wide-bodied aircraft also have a rail-and-roller conveyer system. The military rail system provides a means of guiding and final positioning of pallets within the aircraft and locking the pallets in place for restraint. It is also a key to mass airdrop procedures. Civil aircraft normally have side guides and end locks positioned fore and aft of unit-load devices for restraint.

The civil systems do not engage notches in the 463L system pallets as military rails and locks do. The military rail system is not adjustable. The gauge is 108" in the C-130, C-141, and C-5. The civil systems are adjustable and can handle the military pallet as well as civil ULDs. Military aircraft (except the KC-10A) cannot handle civil ULDs without some type of modification or use of "slave" pallets.

The Food and Machinery Corporation Model MDL (Main-Deck Loader) is a typical civil loader and is the most widely used for servicing wide-bodied aircraft worldwide. Its characteristics and capability are as follows:

| characteristics | feet | inches | ||

| lifting capability: main platform, 40,000 pounds; bridge, 15,000 pounds |

main platform height |

[max [min |

18 1 |

4 7 |

| lift/lower speed: 45 fmp* conveying speed: 60 fpm* |

bridge height | [max [min |

18 8 |

4 4 |

| engine: 391 cid** V-8 industrial gasoline (diesel engine optional) |

main platform length main platform width |

23 10 |

3 8 | |

| ULD capacity: The main platform can accommodate one 8 x 8 x 20-foot container or two 8 x 8-foot x 125" containers or pallets transversely or longitudinally |

bridge length bridge width |

14 10 |

2 8 |

*fpm = feet per minute

**cid = cubic-inch displacement

In addition to servicing the main decks of wide-bodies—as well as the DC-8, B-707, and B-737 cargo-capable aircraft—the Main-Deck Loader (MDL) can also be used for loading/off-loading the forward and mid-lower lobes of the B-747. The DC-l0/L-1011 aircraft, with forward lower-lobe cargo doors capable of accepting standard cargo pallets (as opposed to nartower containers like LD-3s) can also be serviced with the MDL. Some DC-10 and L-l011 aircraft forward lower-lobe cargo doors are too narrow to accept standard pallets.10

Air Force-owned transporter loaders, such as the 40K, reach only to a height of 13 feet. That is too low for the main deck of wide-bodies, which range from 16 to 18 feet. Elevators are used only to lift or lower cargo to and from the aircraft’s main deck. Mobile loaders differ from elevators in that they raise cargo by a scissors mechanism rather than by platform and corner posts. Like elevators, however, they are not designed to transport cargo.

The 13 (25,000-pound lifting capability) elevators and the 29 (40,000-pound capability) elevators have been delivered to the Air Force. (See Table II.) A contract has not been let for the 40 additional elevators and 16 lower-lobe loaders.

The loading doors and main-cargo decks of wide-bodied aircraft are very high, necessitating the use of specialized equipment. If materials-handling equipment interoperability can be achieved between military and civil aircraft, costs such as the $10 million can be avoided, or at least reduced.

Materials-handling equipment is installed at air installations worldwide for loading the main decks of wide-bodied aircraft. Such equipment is controlled by civil agencies such as the airline industry as well as by activities like the U.S. Air Force, airport authorities, and airport-service companies.11

|

type of |

number | time frame |

lifting capability (lb) |

$ cost (millions) |

| elevators | 13 | on hand | 25,000 | 1.0 |

| elevators | 29 | on hand | 40,000 | 3.4 |

| elevators | 40* | FY82, 84 | 40,000 | 4.0 |

| lower-lobe | 16* | FY82, 84 | 15,000 | 1.6 |

| totals |

98 |

$10.0 |

*Tentative quantities pending requirement validation

The 463L system loaders are suitable for loading commercial freighters (where enough lift height is available, as on the B-707/DC-8). However, the typical civil loader is incompatible with the military freighter. The cab/engine complex generally fits under the commercial aircraft, whose cargo floor height is higher due to its low-wing configuration. The military transport floor is low to the ground and impedes the passage of the loader cab beneath the cargo ramp, thus preventing the interface of the equipment to the aircraft.12 The overall MHE requirements could be reduced substantially if more interoperability could be achieved, thereby eliminating duplicate sets of MHE.

The DC-8-63CF (convertible freighter) aircraft can transport 18 loaded 463L system pallets or 18 civil pallets. This is possible because the gauge of the aircraft rail system is adjustable and can accept the 108" greatest dimension of the 463L system pallet or the 125" greatest dimension of the civil pallet. An increase in main-cabin volume of about 11 percent results from the use of the civil 125" pallets, which is undoubtedly the primary reason why civil airlines use them. Over and above the increase in productivity that results from the use of larger-size civil pallets, they also weigh less than the 463L system pallets. The 463L system pallet and nets weigh a total of 355 pounds; the civil 88" X 125" pallet and net, 284 pounds; and the civil 96" X 125" pallet and net, 298 pounds.

(As a point of interest, the C-130 and C-141 aircraft cargo-compartment width is only a few inches too narrow to accommodate the civil-air-cargo 125" pallet with lateral orientation. This subtle dimensional deficiency may have substantially kept these civil derivatives out of major trunk carrier fleets because of their inability to carry efficiently the prime DC-8/B-707 freighter unit-load devices.)

Since civil and military aviation pursue somewhat different roles, it is unlikely that their areas of responsibility will ever completely coincide.13 For example, the military has a requirement for inflight offloading of cargo and troops (airdrop), while the civil carriers have little, if any, interest in airdrop capability. However, a measure of interoperability exists between civil and military air because U.S. civil-air carrier, cargo-capable aircraft can accept 463L system pallets, but military aircraft, except for the KC-10A, cannot accept civil pallets. The civil capability of the KC-l0A exists because the aircraft is a military adaptation of the DC-l0 convertible.

This civil-interoperability capability results from airline responsibility in conjunction with CRAF, the carriers’ need to interline ULDs of varying dimensions, and the carriers’ need to transfer ULDs between different transport aircraft within individual airlines.

The civil wide- and narrow-bodied aircraft are able to adjust the gauge of their rail systems. Military aircraft have not had this capability in the past.

Certain structural and functional differences between the military 463L system and various civil cargo-handling systems constrain the full amalgamation of the two systems. Yet, civil industry and the military have considerable potential for increased interoperability.

Every effort should be made to pursue commonality, especially when new transport aircraft, materials-handling equipment, or unit-load devices are designed and when both military and civil interests can benefit and neither is counterproductively impacted. Such cooperation would be consistent with the Department of Defense guidance (concerning the development of the proposed C-X/C-17 military transport) which indicated: "Cargo handling and container/pallet restraint systems will be compatible with appropriate civil and military systems."

Hq USAF

Notes

1. W. Graham Claytor, Jr., Deputy Secretary of Defense in the approved C-X (C-17) Mission Element Needs Statement (MENS), 28 November 1980.

2. Lieutenant Roger W. Roberts, "A Comparison of Military and Civil Air Cargo Systems" (Monterey, California: Naval Postgraduate School, September 1979).

3. H. F. Morrison and C. B. Wright Society of Automotive Engineers, Inc., Technical Paper 69033, "Advanced Cargo Handling Systems," October 1969, p. 1.

4. Letter from the Douglas Aircraft Company, Long Beach, California, to Hq USAF/SAGM, 29 May 1980, signed by Ralph L. Merrill.

5. "Increased Standardization Would Reduce Costs of Ground Support Equipment for Military Aircraft, "Comptroller General Report to Congress, 7 February 1980.

6. World Airways Introduces the Super DC-8-63CF, Brochure, Douglas Aircraft Company, Long Beach, California (undated).

7. Military Airlift Command, "Monthly Civil Reserve Air Fleet (CRAF) Capability Summary," Scott AFB, Illinois, 1 December 1981.

8. Assistant Chief of Staff, Studies and Analyses, Hq USAF, "Interoperability of Military and Civil Air-Cargo Systems (SABER READINESS — LIMA)," February 1981.

9. 463L Materials-Handling Equipment System, Technical Manual, T.O. #36M-l-l41 (Air Force Logistics Command, Robins AFB, Georgia, November 1974).

10. Letter from FMC Corporation, Airline Equipment Division, San Jose, California, to Hq USAF/SAGM, 27 October 1981.

11. 747 Cargo Facility and Equipment Planning Document D6- 0108 (Seattle, Washington, July 1981).

12. Letters from Lockheed-Georgia Company, Marietta, Georgia, to Hq USAF/SAGM, 11 June and 20 August 1980.

13. John F. Shea, Hq Military Airlift Command, "Route to Airlift Mobility through Partnership (RAMPART)," (AIAA Paper 80-0934), May 1980.

Contributor

Paul D. Tuck (B.A., University of Massachusetts; M.A., University of Maryland) is a transportation analyst with the Office of the Assistant Chief of Staff, Studies and Analyses, Hq USAF. His previous positions include Deputy Director of Transportation, Hq MAC, and planning officer, Hq DA. Mr. Tuck won a nationwide contest sponsored by the International Materials-Management Society for a technical paper he wrote, and he has prepared several major studies on materials-handling equipment and air-cargo systems. He is listed in Jane’s Who’s Who in Aviation and Aerospace (U. S. edition).

Disclaimer

The conclusions and opinions expressed in this document are those of the author cultivated in the freedom of expression, academic environment of Air University. They do not reflect the official position of the U.S. Government, Department of Defense, the United States Air Force or the Air University.

Air & Space Power Chronicles Home Page | Feedback? Email the Editor

Last Updated: 14/Aug/2004 10:03