StarLifter

The C-141, Lockheed's High Speed Flying Truck

by Harold H. Martin

So We Flew

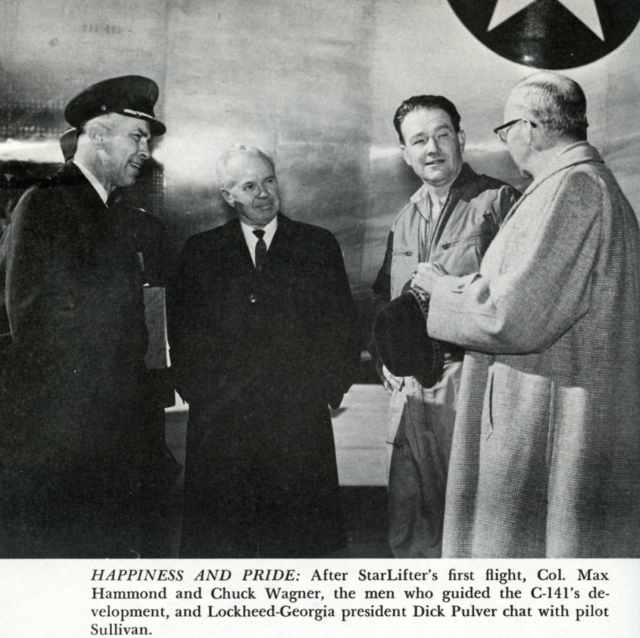

THE JOINT Air Force-Lockheed organization that put the StarLifter together represented a change in management policy for both the military and the manufacturer. Not since the Wright brothers had two men worked so closely together to produce a plane as did Chuck Wagner and Max Hammond, and the staffs of experts assigned to each were equally compatible.

To make up his team Chuck Wagner borrowed a key man from each of the main departments-usually the bright young assistant to the department chief. From Al Cleveland in Engineering he got Bob Gilson. He took Bob Gann from Planning; and Bob Williams from Master Scheduling became his deputy and troubleshooter, working with Jack Mann from Procurement, Lee Poore from Manufacturing, L. L. Jackson from Inspection and Quality Control, Gordon Forbes and Tom Haley from Development Testing, and Charles Bollech from Production Test. Johnny Ferguson was in Contracts, and Mark Cham-berlin in Finance, and to negotiate with suppliers Wagner imported John McCarthy from the California company, a big Irishman with a booming voice who had vast experience in the delicate art of subcontracting.

These subchiefs in turn picked from the working levels in their departments the men with the talents and skills needed to build the StarLifter. They reported directly to Chuck Wagner and took their orders from him, thus bypassing the normal lines of communication and the normal channels of command. Their responsibility to their own department heads was merely to keep them informed of StarLifter's progress-and to ask for special help from a department whenever extra effort was needed. Thus the StarLifter group-7900 men out of a total work force of 18,000-became a close-knit, almost self-supporting organization, but it had close ties at every level with every other department of the company.

For Chuck Wagner it was no great task to put this organization together and make it work, for the men he needed were eager to prove themselves on the new project. They were all young, but in the aviation business men start young, and they acquire vast experience at an early age. The men Wagner chose as his top assistants had worked for many aircraft companies all over the country and they were from widely varied backgrounds. Some were the products of top engineering schools; others, like Wagner himself, had come up from the production line, learning as they went. But each was a thoroughgoing professional, and each man knew his job.

Chuck Wagner knew all their jobs. A child of the Depression, born in Texas and raised in California, he was a product of Inglewood High School, where he studied agriculture, and of Bakersfield Junior College, where he took a brief interest in oil geology. He worked as a vegetable peddler, as a roughneck in the oil fields, as a migrant farm worker, and finally as a freelance tool-and-die-maker, a trade he had learned by mail. Then, in 1932, he went to work for Lockheed as a toolmaker, at a salary of sixty-nine cents an hour. The company was young and so was he and they grew up together. He worked up through the manufacturing end, step by step, taking night school courses in marketing all the while on the reasonable theory that it did no good to make airplanes if you didn't know how to sell them. When the C-I41 competition began, he was Executive Assistant to Dan Haughton, then Executive Vice-President of Lockheed Aircraft Corporation, who was soon to step up to the presidency.

As Haughton moved up, Wagner moved up and on, to Georgia and the challenge of the 141. In thirty years of steady progress up the Lockheed ladder he had become thoroughly familiar with every job connected with building and testing an airplane.

"If you've been working with the engineering people enough of your life," he says, "and with the tooling people and the manufacturing people and the materiel people and the finance people-then you begin to understand how all their jobs kind of link together and mesh in with each other. So, the secret of getting people to work with you is to get them to see that they are part of a team effort, and that you have confidence in them as a part of that team. Then you have to let them know that you understand their problems, by supporting them through their rough spots all the time, though you have to be persistent enough and persuasive enough to insure that you get out of them what they really want to do for you.

"We had a good group on the StarLifter all the way from the top engineer to the hourly people. I'm a great believer in going out tramping the orchard, so to speak, seeing what's going on, and sometimes I'd go out there on the floor at two o'clock in the morning, and there'd be a foreman or a supervisor from the day shift there, checking just to see that the assemblies he was responsible for were going together right. He had gone home, when the shift ended, maybe he'd even gone to bed. Then he thought about something he ought to check on, and came back."

One thing that gave Chuck Wagner confidence was the caliber of the Air Force people the Systems Command had assigned to work with him. He and Max Hammond, the tall, unflappable Michigander chosen as SPO (Systems Programs Officer) for the 141, hit it off from the start.

"We had a lot of faith in each other and our capabilities," says Wagner. "So that meant we didn't always go by the so-called book. Whenever we had a problem-technical, contractual, schedule, or whatever-we'd get our people together and sit them down and tell them to stay with it till it was worked out. There never was a time we felt there was a problem we couldn't solve."

Hammond's Air Force staff matched Wagner's in competence.

"They put together a real good team for me," says Hammond. "All of them were capable, dedicated individuals. My chief engineer was Paul McKee, who went on to become chief engineer on the F-15, the new fighter. Jack Leet was my deputy. Colonel Charlie Craig was the Military Airlift Command representative. He later went to Hawaii as chief of maintenance for the wing there. Colonel Don Bussey was the logistics man. Colonel Tom Flynn headed up my production test organization. He went from Wright Field to Systems Command Headquarters at Andrews Air Force Base. Colonel Joe Marlin did a completely outstanding job for us out at Edwards. We had three airplanes in the service tests out there and he did something with one of them that had never been done before or since. In a project called Petunia Pig we put twenty-five hundred hours of flying time on one airplane in one year, so we could tell what maintenance and logistics problems we were going to run into on down the line. That was the sixth airplane off the line. When that plane performed as it did I knew we had nothing really to worry about. We had what Chuck Wagner said we were going to have, a good program and a good airplane."

Though Max Hammond and Charles Wagner, with their extreme competence, could have made almost any system work, their task was made considerably easier by the administrative changes mentioned earlier. In the past, on the Air Force side, authority to say "yes" or "no" to a contractor's proposal for a fix that would reduce weight, save manufacturing costs, or increase efficiency was scattered through a half-dozen agencies. Under the Systems Program Office set up for the C-141 Max Hammond had his own engineers, his own logistics, manufacturing, finance, and contract experts, his own training command people and FAA and Army representatives. Meeting around a table with their Lockheed counterparts, either in their own shop at Wright Field or at the Lockheed plant in Georgia, they could come up with a proposed solution to a problem in hours, instead of days. Then it was up to Wagner and Hammond to make the decision, and neither of them was inclined to dawdle.

"Early in the game," Max Hammond says, "we decided between us that we were going to make the decisions. We weren't going to push them on up to higher authority, for both of us knew you don't necessarily get the best answers that way. Normally you get the best decision at the level where the detailed information is available. All the higher echelons know is what somebody down in the working ranks has told them, and their knowledge is sometimes incomplete. And that's the way we ran the program. We kept our superiors advised, but we didn't run to them for help."

Much of the impulse to pass the buck to higher authority, Hammond pointed out, stems from a mutual distrust that too often prevails between government representatives and their contractor counterparts. Cartoonists like to depict the two as cozy bedfellows, callously conniving to fleece the taxpayer. Actually they are most often adversaries, watchful, wary, and highly suspicious of each other's motives.

"The military representative has to be in the driver's seat," says Hammond, "for he represents the customer. But he too often acts as if he thinks the contractor is out to cheat him, out to do a less than optimum job and charge too much for it. He keeps looking for booger-bears around every corner, and he is so afraid of making some small concession that might be criticized by his superiors, he holds the contractor's feet to the fire over contract items that really don't make that much difference. On the other hand, the people on the contractor's side are prone to take a dim view of the intelligence of the military. They look upon them as having all the bad characteristics the public likes to attribute to the military mind and the bureaucratic attitude. This kind of mutual distrust can cripple a program."

It evidently did not exist to any appreciable degree while the StarLifter was being built.

Many of the decisions Wagner and Hammond had to make together involved changes that could cost hundreds of thousands, even millions, of dollars. They made them, and then moved on without delay. In one period of less than a month, forty-two changes were either approved or disapproved.

"We'd work it like this," says Hammond. "The Lockheed people would put together the facts as they saw them. Our people would review the facts. Then we'd get all the people we needed in a room together while both sides discussed the pros and cons of every change. There was no squabbling, no table pounding. If you lay all the facts on the table, and your judgment of what should be done is not warped by the misconception that the other guy is out to cheat you in some way, then the solution is pretty obvious and easy to agree on.141 STARLIFTER

"So we made these decisions and made them promptly. If we hadn't, we never would have rolled the first airplane out on schedule, and we never would have made the first flight on schedule."

The roll-out actually occurred a week earlier than the date that had been tentatively selected three years before. On August 22, 1963, President Kennedy pressed a button on his desk, setting off a series of electronic relays that lifted the great doors of the StarLifter's hangar in Marietta, Georgia. Pulled by a yellow tractor, the big plane trundled slowly into the sunlight.

It was, the President said, "a great moment for our nation." Chuck Wagner remembers looking about him at the throng of dignitaries on the platform and thinking, "We can't have a war today. All the top generals are tied up down here." So were a number of the nation's top political figures, including Senator Barry Goldwater, a jet pilot himself and an Air Force Reserve general, who left no doubt in the minds of those present that he was going to be a candidate for the presidency in 1964.

By mid-December this first plane had passed all her ground-handling tests and was presumably ready to fly. No definite date was announced, however, for small last-minute fixes may cause a first flight to be postponed.

Late in the morning of December 17, Chuck Wagner telephoned Leo Sullivan, Lockheed-Georgia's chief engineering test pilot. "Leo," said Wagner, "what do you think?"

"I think," said pilot Sullivan, "that I am going to have some lunch. After that, I am going to go out and taxi around awhile. Then, if everything feels all right I might just keep on going."

"You go, Leo, if you feel it's all right," said Chuck Wagner. "But don't you take off, regardless if there are ten thousand people standing around here, if it doesn't seem just exactly right to you. This thing means too much to us."

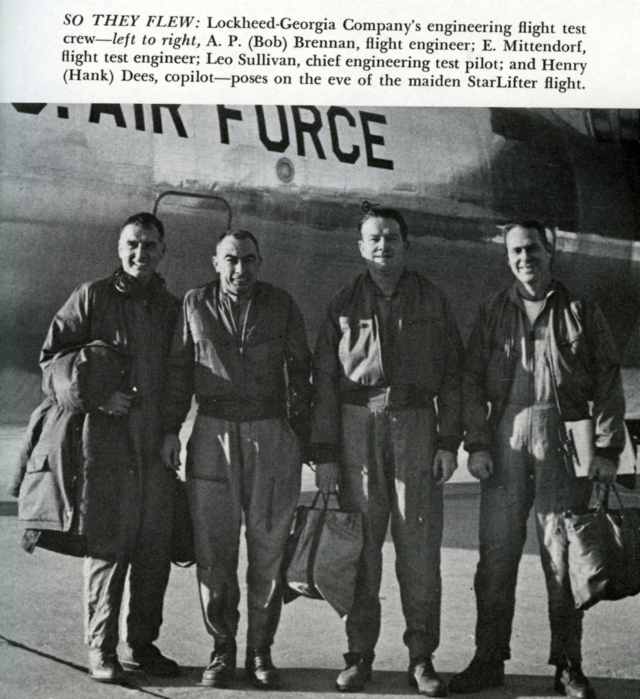

"Don't you worry," said Sullivan, a big, long-headed, plain-spoken Californian, an ex-Navy pilot who describes himself as "just a big dumb Irishman with a lot of luck." "I've got a personal, built-in flight instrument that tells me when it's go or no. That afternoon, with Hammond, Wagner, and several hundred engineers and others who had gotten wind of what might happen looking on from the tower and the flight line, Leo Sullivan taxied StarLifter #1, T-tail 61-2775, to the head of the 10,000-foot runway at Dobbins Air Force Base. Beside him in the right-hand seat was engineering test pilot Hank Dees, a Ten-nessean by birth. Graduated from Auburn University, Alabama, in aeronautical engineering, he also was a graduate of the Air Force Test Pilots School. At the flight engineer's console was a cheerful Irishman named Bob Brennan, educated in England and a long-time flight engineer with Imperial Airways before it became BOAC. Backing him up as test-flight engineer was E. "Mit" Mittendorf, a Texan.

The big plane paused at the end of the runway for what to those watching seemed an unusually long time. Was something wrong? Then suddenly the engine noise rose to a wild scream and the plane began to quiver, straining against the brakes. It held there shaking until the engine revved up to takeoff power. And then it began to roll, slowly for a second or two, then fast, and then faster, and faster, and faster, and everybody realized all at once that this was no high-speed taxi run, this was a take-off roll, and in the tower Max Hammond, usually so calm, found himself shaking so that he could hardly keep the plane framed in the viewfinder of his borrowed camera, as Leo Sullivan eased the yoke back to his bellybutton and the first StarLifter, light at 190,000 pounds, rose gracefully and easily into that ocean that was her natural element, the air. They took her up to 8000 feet and flew around for fifty-five minutes, and then brought her gently down. It was, by coincidence, the sixtieth anniversary of the Wright brothers' first flight.

The cameramen were waiting for Leo and his crew, and he explained that it was all very simple. "We just rolled down the runway until there was nothing left to do but fly. So we flew."

One of those watching, hollow-eyed from days and nights of work to get this plane ready for its maiden flight, was Tom Haley. A lean, tall, Lincolnesque engineer, he had shepherded the plane through its fatigue and static tests, and later was to direct its flight-test program. "When that plane roared down the runway and lifted into the air, I think I know how a woman feels who has just had a baby," Tom said. "The same feelings of weariness, and happiness and pride and accomplishment and deep emotion. . . ."

Said Gordon Forbes, English engineer who was flight-test director when the C-141 made its first flight: "I too was deeply stirred, but my emotions were more those of the anxious father than of the mother. I felt a strong urge to go home and have a whiskey."

Everybody who had anything to do with producing the Star-Lifter was beaming happily and shouting, slapping each other on the back, and congratulating Chuck Wagner, the man who'd brought the big plane in on time and in the money.

"All right, all right," said Wagner, pretending gruffness. "Let's celebrate for about ten minutes now. Then we've gotta get to work and get those planes rolling out.