Over the years NASA has had a lot to do with the C-141, and has used them for

research in many areas. If you flew or did experiments on #714, it would be great

to get some information or photos from you about the program.

Here's a note from Wally Stahl who was associated with 714 for many years.

December, 2005

A Story of One Airplane With Two Lives

AF C-141, Serial #6110, also known as the Lockheed L-300 registered as N4141A and

later as NASA N714NA.

By W.G. 'Wally' Stahl

The first life had its beginning when the Air Force and

“others” approved Lockheed procuring the 110th

C-141 off the assembly line in order to demonstrate its capability as a

commercial cargo carrier.

The purpose was to get enough commercial and possibly other government orders to

extend the production line beyond the programmed 285 orders.

I hired in at Lockheed in 1963 at the beginning of the C-141 program as a

licensed A & P mechanic on the flight test airplanes. At that time there were

only two C-141's completed, one flyable and one in the hanger with plenty of

engineering changes to be made. From the beginning, the C-141 was to be

simultaneously FAA certified with the Air Force certification and there were

mixed flight crews on some of the flight tests. The first eight units were

programmed as flight test airplanes, each with different test programs. As they

came down, I was appointed a supervisor initially relieving the other supervisors

as this was a seven day a week , 24 hour a day operation. I was then given a crew

of my own on the enviromental test airplane. I was happy when the production

flight airplanes began coming down as I was interviewed by the Chief Flight

Engineer and signed on as a production flight Flight Engineer. A full crew, two

pilots, two FE's, and a navigator would spend the better part of a day checking,

inspecting the complete airplane that maintenance had opened all engines,

inspection plates, and panels, then engine runs and slow and fast taxi to check

brakes, spoilers, etc.and writing up the discrepancies. Usually these would be

worked off by morning and after checking them, we were ready for a four hour test

flight, checking in flight door and ramp operation, plumbing for leaks, etc.

The Flight Engineer's other job in Production Flight was developing the study

guides for each system and teaching the ground school to the Air Force

instructors and early Flight crews.

As serial #6110 came down the assembly line, I was notified by the Chief Flight

Engineer that I was being given the Project Flight Engineer's job on it, along

with veteran pilot Gene Whitton as Project Pilot we were to follow it along and

make sure it would be operated as an FAA certified airplane.

It was welcomed to the flight line in April 1966 with its white and red stripe

Lockheed colors. It got plenty of visitors including Gene and I.

The first test flight was on May 4,1966 of four and one-half hours. The first

cross country was on 5-23-66 to O'hare for a cargo symposium.

That was the beginning of 713 flight hours which ended on 7-3-1968.

In that period it visited 38 US airports including Hickam (some cities multiple

times) and 31 foreign airports ( some multiple times). They included Canada, nine

European cities, Africa, Australia, New Zealand, Turkey and Iran.

These flights involved demonstrating short field landings and takeoffs, loading

outsized cargo, paratroop drops and flight characteristics.

There were a couple of incidents that were interesting to say the least.

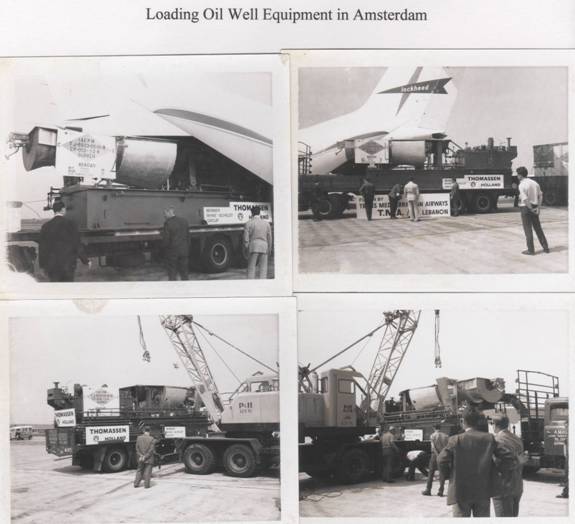

In 1967 during a Mid East conflict, Egypt had blocked the Suez Canal and all sea

commerce had to go around the tip of Africa, adding many days for delivery. At

this time, Iran was an ally of the US and they badly needed some new oil well

machinery that was manufactured in Holland. This machinery was of a size and

weight that no other aircraft was capable of transporting it from Amsterdam to

Abadan, Iran.. Through the State Dept. we were approved to fly this equipment to

them. I was given the weight and size (dimensions).It was a huge steel piece 29'x

9'x 8' high weight= 46,680 pounds.It was immediately obvious that sitting on two

pallets and the rollers that it would not go in the pressure door opening.By

doing some figuring we decided if we could come up with something thinner than

the pallets, we could get it in. We knew it had to be strong and the only thing

we came up with was to get a steel plate 3/8 inch thick just wide and long enough

for the base of it and with holes for 25 thousand pound chains, it would go in..

We had them load it on the plate and rollers on the flat bed truck the same

height as the ramp and back it up to the ramp.. As they got closer we saw that it

was going to hit the little metal flag that shows the pressure door is locked in

the up position so we had to remove that and it just went in. We winched it in to

where it was over the wheels (center of gravity) and chained it down. There were

other big crates that were loaded in front and back. The trip over was uneventful

until after we landed and saw that they didn't have a flat bed vehicle to load it

on. It was late in the day and they told us to go to the hotel and they would

have the equipment the next morning. The next morning they had us open the back

up and they began building a stack of what looked like railroad ties behind the

ramp and they wanted us to unload it onto rollers on the stack and they would

load it on a truck. Since we had no other option, I told the pilot to be ready to

start up the two outboard engines when I gave him the word and taxi out away from

the stack. Fortunately everything worked but it was a shaky operation.

Another amusing incident was on a Demo for a freight airline out of JFK to

Frankfurt and then to Zurich to load a large milling machine. It was late when we

got there and decided to stay overnight. The German supervisor for the airline in

Europe was to get help loading the milling machine but told him to wait until

morning. We gave him the key to the plane so he could get everything ready to

load and told him to not try to load it without me being there. There was a lot

of snow on the ramp where we parked and it was still snowing. The next morning we

went over and the German was waiting for us. I went in to start up the APU to get

the pressure door open and nearly s**t myself as the milling machine was loaded

on a pallet on the bare floor,no rollers. I called the pilots to come take a look

and we asked the German how they loaded it as there were no skid marks on the

floor. He said he couldn't find the rollers so he had his crew get some buckets

and piled up snow on the cargo floor and ramp and slid the machine in to where he

figured it would be near the center of gravity. He had cleaned the snow out and

dried the floor so you couldn't tell it. We chained it down and and took off

wondering how they were going to unload it in New York.

By July of 1968 it became apparent that there was not enough interest in

commercial use of the C-141 so after 704 flight hours it was put to rest on the

ramp on July 3, 1968. Our maintenance crew periodically checked it over hoping

someone could use a practically new Airplane.

Word came from Marketing in late 1970 that NASA was looking for a large four

engine plane to install a large telescope to do high altitude astronomy.They got

word of our C-141 and sent a crew to look it over and began negotiating for it.

Needless to say, they got a good deal. Lockheed brought it up to date and put the

NASA paint job on it Our flight crew did a complete inspection and pre-flight and

flew a four hour test flight on

01/31/1972. We flew an acceptance flight with a NASA crew on 02/02/72 with the

Chief of NASA Flight Operations, George Cooper and it was turned over to NASA. We

flew with a NASA crew to Ames Research Center at Moffett Field, California on

02/03/72. We did a number of training flights with the NASA pilots and on

07/31/72 ferried it to Lockheed Aircraft Services in Ontario, CA for major

modifications to install the telescope hardware and support equipment. This

included building a cavity inside the fuselage that would withstand the aircraft

pressurization as the telescope would be exposed to the outside atmosphere. This

modification was completed the latter part of March 1973 and after a thorough

inspection and ground runs checking pressurization and all systems, we flew test

flights on 4/6 and 4/11 and ferried it back to Moffett on 4/25/73. These were the

last entries in the original log book and showed a total of 791 hours on the

aircraft.

During the modification period, the Chief Pilot at NASA requested that I come out

and give his pilots that would be flying the C-141 a couple of weeks of ground

school so I made up a plan and since they didn't have a Flight Engineer, they

picked one of their mechanics to be in the class. I conducted this class in March

and at some point prior to going to Ontario to check out the mods, the Chief

Pilot George Cooper who had attended the ground school, called me in and inquired

if I would be interested in the Flight Engineer's job at NASA. It didn't take me

long to say yes. The paper work was started and on July 30, 1973 I departed

Lockheed and joined NASA Flight Operations.

The last six months of 1973 were utilized in telescope equipment installation and

check out, and training flights of only 52 hours.

This aircraft began to arise to it's new life in 1974 when it began to do serious

high altitude astronomy as the Gerard P. Kuiper Airborne Observatory. These

flights were normally scheduled for eight hours. We carried a fuel load of

105,000 # which allowed us to reach flt level 370 and as we burned off we stepped

up until we reached 410 and maintained it.The astronomers desired to reach as

high an altitude as possible to minimize the water vapor in the atmosphere. On a

few occasions we operated at 45,000.

Our heavy maintenance and major checks were accomplished at Travis AFB and our

Crew Chief, Lloyd Domeier had a good working relationship with their people, so

we got great service. Lloyd was an excellent Crew Chief and always went the extra

mile to get us off on time as we had to be at a particular point on time for the

astronomers to begin their science.

We normally were scheduled for three flights a week (always at night) and I had

checked out the mechanic as a Flight Engineer and we were flying every other

flight. As time went on the astronomers were getting approval to do astronomy out

of Hickam and that led to not only many more flights back but flights out of Pago

Pago, New Zealand to study Halley's comet, Guam and Yakota for total eclipses and

Australia. We even under flew an early shuttle reentry out of Honolulu to measure

the under wing tile temperatures using the infared telescope. On another occasion

we tracked a missile launch out of Vandenberg.

Finally, after 21 years this magnificent machine was permanently laid to rest in

1995. I had retired in 1988 after 15 of the most rewarding years of my life.As

well as my many experiences with the C-141, I had checked out early on NASA's

Convair 990 and made many trips off base to India, Alaska, Norway, Europe,

Mexico, Bermuda, Puerto Rico, Barbados, Costa Rica, Panama, Brazil and Guatemala

, and to put the icing on the cake, NASA had procured a DC-8 in 1986 and had it

modified and ready for science in 1987 and my last deployment was a trip to Punta

Arenas, Chile checking out the hole in the Ozone Layer and included a low pass

over the South Pole.

Here's a snapshot of my 48 years in the Aviation World.

U.S. Army Air Corps—9/20/1940—10/21/45 Air Corps Technical

School

Chanute Field, IL,Aircraft Mechanic, Moffett Field, CA,Chico,CA,Boise,ID,

Pendelton, OR, CA Desert. CBI Theater, two years China 14th AF.

Spartan School of AeronauticsTulsa OK, 12 Months A&P License

15 years Eastern Airlines, 10yrs. Miami, Fl Aircraft Overhaul,Flt line Lead

Mechanic.

On time off –Flight School-Commercial, Instrument, Multi-Eng, Flight

Engineer ratings.- Recip, Turboprop,Turbojet, Ground School Instructor

5 years-Flight Engineer Eastern, Connies, DC-7, L-188 Electra. NY, New Orleans,

Atlanta.

10 years Lockheed Georgia Co. Marietta, GA. A&P mech, C-141 Flt. Test,

Supervisor, C-141 Flt Test Crew, FE on C-141 and C-5A production Aircraft, Ground

School Instructor-C-5A Systems Operation to Altus AF instructors and Wright Pat.

Engineering Personnel. Project FE on L-300

15 years NASA Ames Research Center, Moffett Field,CA Senior Flight Engineer and

Instructor, C-141, Convair-990, C-130, DC-8.

Here's a note from Lloyd Domeier, who was associated with 714 for 21 years.

September, 2005

We got good treatment from the USAF and we never had to stage on other units

aircraft like during Vietnam missions. However, I did spend a lot of time in the

Air Force taking off at sundown and landing at sunup!!

My first trip to Hickam was 1957 to spend a month in C-124 maintenance school and

many more trips there since, I figure I have been there about 120 times. I also

did my share of flying out of Mildenhall all over Europe in old shakey {C-124}

I was active duty from 1957-1961 and got recalled in 1968 for two more years

because of the Pueblo incident.

The old "I was in the right place at the right time" applied to me.

I was working at Travis in 1973 when I saw this beautiful blue and white 141 taxi

in for fuel cell maintenance.

I found out were it came from and called the chief of maintenance at NASA Ames

and asked for a job. He said come in and talk to him. I did and got hired on.

Three months later I was promoted into the crew chief slot which I held for 21

years.

Had a great job and met lots of interesting folks. Only shut down one engine in

flight in all that time. We were on the way home from Christchurch N.Z. and after

refueling in Pago Pago Samoa going nonstop to Ames we lost all the oil from # 2

engine. We diverted to Hickam and replaced a cracked oil line. Two hour later we

were airborne again.

Had two in-flight failures, one after take off from Travis when we took a goose

in #2 engine, the other one was on take off from Christchurch, the pins holding

the turbines on #3 engine sheared and locked up the engine.

Last flight was in 1995. My hope is some museum will get 714 and put her on

display.

Lloyd Domeier

Crew Chief NASA 714

S/N 6110

Model L-300

Was N4141A with Lockheed

Became N714NA with NASA

Had about 425 hours when NASA bought it

Total hours now 13,500

The day after the above info was posted this email arrived from James Mills:

I was the Avionics technician on the KAO from 1990 till it was de-commissioned in

1995.

From the time I got on board till the final flight, I took care of all the

electronics, from the Bendix color radar to the T-Tail light, I did all Avionics.

I found out during the first Air Force Depot visit that MAC was not doing what

NASA wanted when it came to the L300 avionics maintenance. On depot visits, I

would sign a waiver during the pre-dock meeting that stopped all the scheduled

avionics inspections and repairs. During the time in depot, I would order

antennas and control panels as required and try to get the parts that NASA could

not get due to our low priority in the Air Force system.

During non depot periods I had great service from the Travis Air Force Base

maintenance supply system. We would call ahead for an AOG (Aircraft on Ground)

part, then fly or drive to Travis and pick it up. We saved many a flight due to

the fast actions of the men and at Travis and MAC.

Whenever we were on the road for oversea missions, the MAC C-141 supply system

would deliver our parts to where ever we were if possible. This was especially

true in Christchurch, New Zealand or Hickam AFB in Hawaii.

If we were away from a US base of operations then we would use air freight. Lloyd

Domeier was without a doubt a great crew chief. He knew the plane so well that my

job was easier when he was on the crew. He was not above changing brakes or tires

or other dirty jobs.

Our crew was composed of three permanent mechanics and one avionics tech with one

instrumentation tech for the telescope system. The Telescope and data acquisition

and management system was contracted out to a subsidiary of Northrop and a

Silicon Valley software company.

The KAO was de-commissioned to make way for the 747 version IR observatory which

should have been airborne in 1998. It has been in construction since 1997. It may

fly in 2006. NASA may7 get to restart IR observatory flights in 2007.

I love the C141 website! I have a few C-141A stories that I will share when I get

a chance.

After years of working on research F-18s and F-15s, I am currently working on

C-17's for a research program here at Dryden Flight Research Center at Edwards

AFB.

Keep up the great work.

Jim Mills

These are some links to pages and photos about this activity.

|

NASA book

|